…We are determined to exponentially impact our clients needs with inventive solutions to their problems.

Ty Harnet – Managing Director – Inventor

FREE DELIVERY WHEN YOU SPEND £125 OR MORE…!

Animation Video

Instructional Video

How does the Clever Coupler benefit installers?

![]() Prevents flux contamination when typically cutting out faulty equipment (soldered sockets upstream and downstream).

Prevents flux contamination when typically cutting out faulty equipment (soldered sockets upstream and downstream).

![]() Minimal loss of corrosion inhibitor when replacing equipment and limiting further problems thereafter. *

Minimal loss of corrosion inhibitor when replacing equipment and limiting further problems thereafter. *

![]() Limits time and system disruption on site for asset owner and engineer. *

Limits time and system disruption on site for asset owner and engineer. *

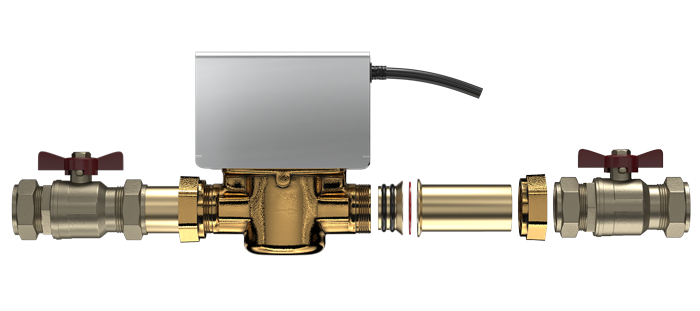

![]() Removes all the associated problems with compression joints – over tightening, micro leaks, the inability to move pipes or equipment after installation.

Removes all the associated problems with compression joints – over tightening, micro leaks, the inability to move pipes or equipment after installation.

![]() Prevents drain downs, risk of air locks or loss of system water.*

Prevents drain downs, risk of air locks or loss of system water.*

![]() Allows the removal and servicing of the integrated strainer within combination valves remotely, preventing leaks from stressing out factory fitted compression joints in situ.*

Allows the removal and servicing of the integrated strainer within combination valves remotely, preventing leaks from stressing out factory fitted compression joints in situ.*

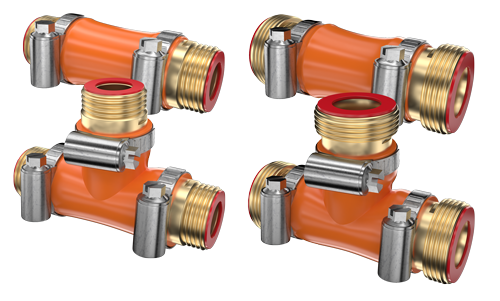

![]() 5 seals over 2 compared to a typical compression joint

5 seals over 2 compared to a typical compression joint

![]()

*When fitting lever valves directly onto stubs provided.

PRODUCT TESTIMONIAL

“A problem I’ve encountered for years is having to replace a system component situated between two pipes that have no movement and being forced to cut the pipe and install a slip coupler after replacing the component. Using clever coupler has solved this problem, as I can install and remove a component without having pipe movement available. This will ensure that any future maintenance tasks can be carried out quickly and stress-free. The clever coupler has a total of 5 seals compared to the traditional nut and olive joint only having 2. The clever coupler is made using DZR brass which is less vulnerable to corrosion compared to cheaper brass fittings on the market.”